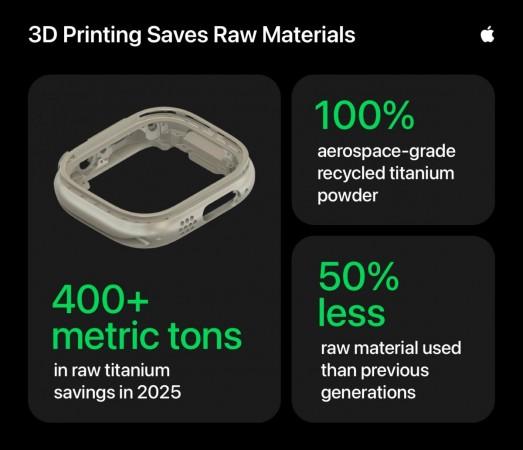

It's been a month since Apple refreshed its latest iPhone and Watch lineup, offering some of the biggest upgrades. But Apple has done the impossible by pulling off a breakthrough that was ong considered unachievable for mass-market consumer electronics. In a major push towards its Apple 2030 carbon-neutral goal, the Cupertino tech giant quietly executed one of its biggest hardware manufacturing shifts ever—moving two flagship Watch models to 3D-printed, 100% recycled titanium enclosures.

Apple's latest Apple Watch Ultra 3 and Apple Watch Series 11 now use 3D-printed cases made entirely from recycled aerospace-grade titanium powder, replacing traditional forging for the first time at a global scale.

Forging into reality

The idea emerged from a simple question within Apple's product design teams: could additive manufacturing—mostly used for prototyping—produce millions of identical, high-precision enclosures?

"When we asked the question, we immediately started testing it," said Kate Bergeron, Apple's vice president of Product Design. "We had to prove this technology was capable of meeting the high standard of quality we demand."

After years of experimentation, Apple now uses a fully additive process that prints the Apple Watch case layer by layer—over 900 layers per enclosure—using six synchronized lasers inside each printer.

Why is it a big deal?

Traditional machining cuts away large portions of metal, but Apple's new process prints enclosures nearly to the final shape.

The result: a 50% reduction in raw titanium use compared to previous generations.

"That means you get two watches out of the same amount of material used for one," said Sarah Chandler, vice president of Environment and Supply Chain Innovation. Apple estimates the new process will save more than 400 metric tons of raw titanium in 2025 alone.

Worked for the better design output

To make the process viable, Apple had to solve complex materials-science challenges—including controlling oxygen levels during titanium atomization and creating powder particles just 50 microns wide.

Once printed, each enclosure undergoes rough and fine depowdering, ultrasonic cleaning, wire-saw singulation, and automated optical inspections before entering final assembly.

The shift to 3D printing also unlocked design improvements previously impossible with forged metal, such as textured interiors for better waterproofing and antenna bonding in cellular Watch models.

Beyond the Watch

That's not it. Apple also revealed that its new 3D-printed recycled titanium process also enabled the redesigned USB-C port on the new iPhone Air, allowing the company to engineer a thinner yet stronger titanium enclosure.

A step toward Apple 2030

Apple emphasized that the change is not a one-off experiment but a long-term manufacturing transformation.

"We're never doing something just to do it once," Chandler said. "Our North Star is to design products that are better for people and the planet."

All electricity used to manufacture Apple Watch already comes from renewable sources such as solar and wind.