NASA will begin licensing one of its patented 3D printing techniques that involve making rocket engine nozzles through additive manufacturing.

The process, called Laser Wire Direct Closeout (LWDC) was developed by the space agency to reduce the time and cost of producing rocket engine parts, reports NASA. The LWDC process is unlike most other 3D printing techniques which involve powdered metals added in layers.

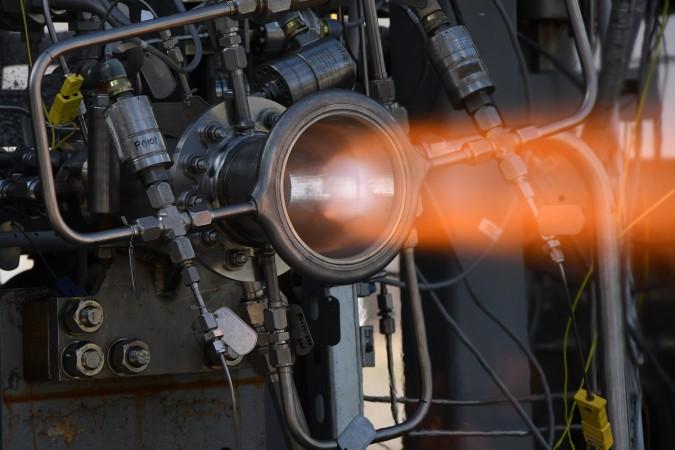

Instead, NASA devised a way to use a "freeform-directed energy wire deposition process" to print the engine part. "What makes this development project even more unique is there were three separate, state-of-the-art, advanced manufacturing technologies used together to build a better nozzle and prove it out through hot-fire testing," said Preston Jones, director of the Engineering Directorate at Marshall.

This process can reduce the manufacturing process of nozzles from a few months down to a few weeks, says the report. Nozzles operate at extremely high temperatures and pressure from a rocket's combustion process, hence is an expensive component to design and build, in spite of looking simple reports NASA.

LWDC makes use of a wire-based 3D printing process that precisely closes off channels embedded within the nozzle that holds high-pressure coolant fluids. This protects the walls of nozzle components from the temperatures that it must withstand.

"Our motivation behind this technology was to develop a robust process that eliminates several steps in the traditional manufacturing process," said Paul Gradl, a senior propulsion engineer in Marshall's Engine Components Development and Technology Branch.

"The manufacturing process is further complicated by the fact that the hot wall of the nozzle is only the thickness of a few sheets of paper and must withstand high temperatures and strains during operation," he added.

After developing the process and patenting LWDC, Marshall built a test-fire nozzle. Hot-fire testing was then reportedly carried out to make sure that it actually worked. So far, the printed test nozzle has undergone over 1,040 seconds of testing at extremely high temperatures and pressures expected during the launch of a rocket.

The licensing process is being done to encourage private and industry partners so that this technique can be used in various commercial applications.