If you are driving, especially on a long road trip, you may ask yourself one thing: What if the tires puncture before you reach the destination?

You can carry a spare wheel or approach a nearby workshop, but that remedy can't be applied to space vehicles that explore the moon, Mars and other planetary bodies.

This is why the US National Aeronautics and Space Administration (NASA) came up with the idea of tires that will never puncture, and the result is impressive.

According to NASA, three types of tires were used in space vehicles in the 1970s. The Russian vehicle Lunokhod used eight rigid-rim wire-mesh wheels with bicycle-type spokes and metal cleats for traction, while the American Modularized Equipment Transporter (MET) used smooth rubber tires supported by nitrogen-filled inner-tubes manufactured by Goodyear.

And NASA's Lunar Roving Vehicle used four large flexible wire mesh wheels with stiff inner frames to prevent over-deflection.

However, these tires had one drawback, and that was durability. So, NASA Glenn engineers developed the "Spring Tire" along with Goodyear in mid-2000s that won the R&D 100 Award for Top Inventions of the Year.

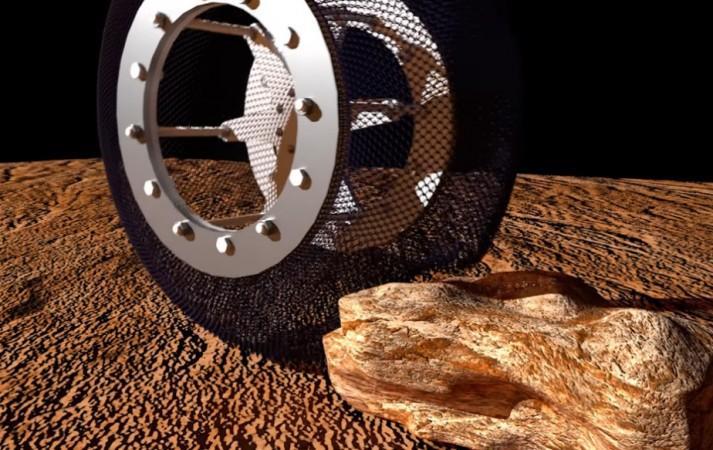

The airless tire consists of hundreds of coiled steel wires woven into a flexible mesh, which give it the ability to support high loads. But the damage to Mars Curiosity Rover wheels after a year of stay on Mars made the engineers improve the "Spring Tire" in terms of traction in soft sand, durability and overall weight.

The game-changing moment came when the NASA Glenn engineers discovered nickel-titanium, a shape-memory alloy. The new alloy tire was then sent to NASA's Jet Propulsion Laboratory (JPL) for durability test: placing it on terrain similar to the one on Mars.

The result was impressive, as unlike the atomic structure that deforms over time, the memory alloy tire re-arranged itself and bounced back to its original shape when stressed.

NASA said in a statement that the new "Spring Tire" (made of memory alloy) has three benefits: It can cover more distance, carry heavier load as it can conform to the terrain without sinking, and can be used on crewed exploration vehicles which are expected to move at high speeds as the tires can absorb energy from impacts at moderate to high speeds.